Volumetric Calibration

DASHINSPECTORATE ensures the ability to precisely measure the quantity (volume) of containment systems/ storage units/ equipment, by adopting international codes/standard practices

Volumetric Calibration is the measurement process to determine the correct quantity/volume of substance the equipment/ tank can actually have. Volumetric tables and quantity measurements are most required to control the stock held in storage vessels and also to estimate the containment

Why DASHINSPECTORATE,

DASHINSPECTORATE ensures the ability to precisely measure the quantity (volume) of containment systems/ storage units/ equipment, by adopting international codes/standard practices. We are well equipped with advanced measuring technologies (such as Robotic Total Station, 3D Laser Scanners etc.) and various analysing soft wares.

Most often, the latest software “Trimble® RealWorks® Advanced-Tank Edition -2019” is being used to produce superior calibration results from 3D laser scan data. It features highly-automated, efficient workflows to thoroughly analyse complex datasets to create volume tables from 3D laser scan data.

The 3D software “Topcon- Magnet Collage” also being used to combine and point cloud processing of disparate and multiple mass data sets into one 3D environment

3D Laser scanning technology empowers to rapidly perform comprehensive and detailed measurement and analysis. Unlike traditional techniques, it can capture the entire equipment structure in detail within the span of a few hours, minimizing scheduled downtime. The unprecedented measurement coverage provides high-resolution point-cloud data to the user and enables further analysis to be conducted. Scans can be captured safely from the ground without interfering with on-site activities.

In addition, DASHINSPECTORATE possess decades of experience in calibration services of almost all static equipments, especially in Oil/Gas, Power, Petrochemicals and Marine sector

DASHINSPECTORATE can offer a calibration table at smallest possible resolution

DASHINSPECTORATE provides calibration services for

API 650; Atmospheric storage tanks.

Pressure vessels (Horizontal/ vertical).

Spheres/ Spheroids/ Spherical Tanks.

Bullet Tanks.

Cylindrical Land Tanks (Horizontal/ vertical).

Industrial Silos

Tanks on Ships & Barges

Rectangular Tanks/ Containers

Concrete Reservoirs

Cross-country Pipe line

Process/ Power piping

Methods can be used

Electro Optical Distance Ranging (EODR) Method -Internal/External

Optical Reference Line Method

Total Station Reference Line Method.

Manual Strapping Method.

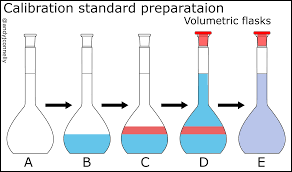

Liquid Calibration Method.

Standards by:

American Petroleum Institute (API MPMS)

International Standards Organization (ISO)

Steel Tank Institute (STI).

Liquid Calibration Method.

Need help or have a question?

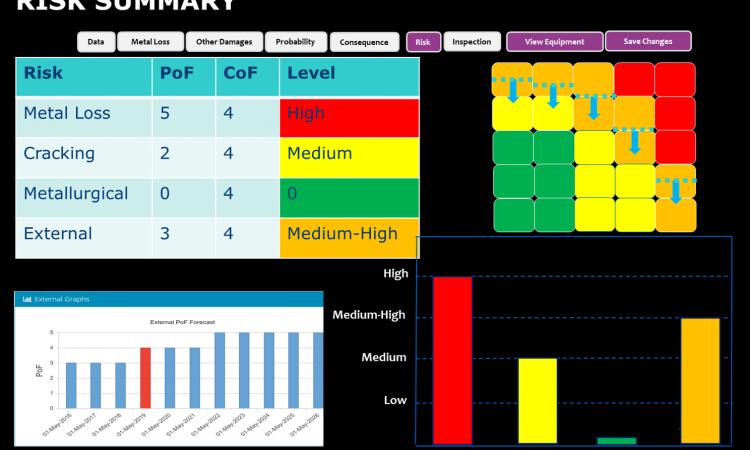

- Risk Based Inspection

- Pipeline Inspection Management System

- Pipeline Inspection Management System (Onshore)

- Structural Integrity Management System (SIMS)

- Pressurized Equipment Management System

- Inspection Scheduling Management System (ISMS)

- Wellhead Integrity Management System (WHIMS)

- Computerized Maintenance Management System

- Asset Performance Management System

- Safety Integrity Level (SIL Study)

- Reliability Centered Maintenance (RCM)

- Reliability, Availability and Maintainability (RAM)

- Condition Based Monitoring (CBM)

- Condition Assessment Studies (CAS)

- Corrosion Management Plan (CMP)

- Corrosion Risk Assessment Study (CRAS)

- Asset Life Extension Studies

- Fitness For Service

- Close Interval Potential

- Direct Current Voltage Gradient

- ISO 55001 (Asset Management Systems)

- RBI Technical Training