Fitness For Service Analysis

Dashinspectorate can offer comprehensive multi-level FFS analysis (along with failure analysis/ investigation, if required) to ensure the mechanical integrity and reliability of assets such as pipelines, pressure vessels, storage tanks etc.

Dashinspectorate can offer comprehensive multi-level FFS analysis (along with failure analysis/ investigation, if required) to ensure the mechanical integrity and reliability of assets such as pipelines, pressure vessels, storage tanks etc. Most often, API & ASME standards would be referred to perform the activity.

We are also well equipped to perform the associated tasks to produce a complete FFS analysis package to our clients, following are some of such supportive tasks (but not limited to)

Field inspection & Assessment.

Ultrasonic pulse velocity testing.

Finite Element Analysis (FEA).

Non- Destructive Tests (NDT).

Mechanical Tests and In-situ Metallography.

Creep, Fatigue & Fracture analysis.

Pressure Tests.

Our detailed analysis sets out a clear program of repair, inspection and mitigation actions, which, when scheduled and completed, ensure safety and reliability.

What is FFS?

Fitness for Service (FFS) is a best practice and standard used by the oil & gas and chemical process industries for in-service equipment to determine its fitness for continued service. FFS serves as a rational basis for defining flaw acceptance limits and allows engineers to distinguish between acceptable and unacceptable flaws and damage based on industry recognized and generally accepted good engineering practices (RAGAGEP).

The FFS of any particular material is determined by performing a fitness-for-service assessment per standardized methods and criteria. Performing accurate FFS evaluations is an integral aspect of fixed equipment asset integrity management as an alternative to using the original construction design code. The FFS of a piece of equipment may be viewed both in terms of current and future FFS or remaining life. Most equipment can continue in service despite small flaws, and to repair or replace equipment that can still be used would be an unnecessary and costly expense. In addition, unnecessary weld repairs can do more harm than good and create unnecessary risks to personnel in many cases

API RP 579-1/ASME FFS-1, Fitness for Service, Second Edition, is one example of a FFS methodology currently used by industry professionals. In general, most FFS assessment standards are broken into multiple levels. Each successive level (e.g., Levels 1, 2 and 3 of the referenced API 579-1/ASSME FFS-1 standard) requires increasing amounts of data, calculations, effort, and cost to arrive at the most accurate outcomes and possible longer equipment remnant life. In addition to calculations, FFS involves the consideration of additional data (e.g. pitting patterns and depths, corrosion morphology or shape and depth, crack depths and lengths, operating conditions, materials properties, etc.). Inspection information is often critical input to a FFS assessment.

Need help or have a question?

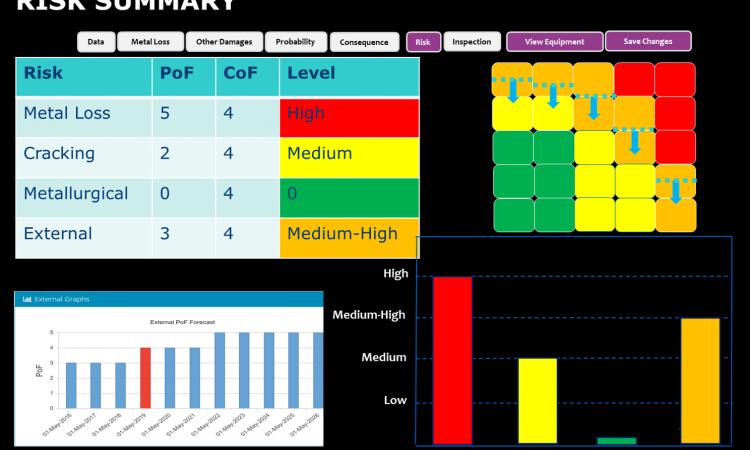

- Risk Based Inspection

- Pipeline Inspection Management System

- Pipeline Inspection Management System (Onshore)

- Structural Integrity Management System (SIMS)

- Pressurized Equipment Management System

- Inspection Scheduling Management System (ISMS)

- Wellhead Integrity Management System (WHIMS)

- Computerized Maintenance Management System

- Asset Performance Management System

- Safety Integrity Level (SIL Study)

- Reliability Centered Maintenance (RCM)

- Reliability, Availability and Maintainability (RAM)

- Condition Based Monitoring (CBM)

- Condition Assessment Studies (CAS)

- Corrosion Management Plan (CMP)

- Corrosion Risk Assessment Study (CRAS)

- Asset Life Extension Studies

- Fitness For Service

- Close Interval Potential

- Direct Current Voltage Gradient

- ISO 55001 (Asset Management Systems)

- RBI Technical Training