HIC and SSC Test

Dashinspectorate laboratory is fully equipped with latest methods of testing in compromise with relevant standards of testing. We perform Sulphide Stress Cracking (SSC) testing of metals subject to cracking with simultaneous effect of tensile stress and corrosion in the presence of wet media and H2S environment as per NACE TM 0177 standard.

As per this test, the metals are subjected to tensile stresses for resistance to cracking failure in low-pH aqueous environments containing hydrogen sulphide (H2S).This type of corrosion is hazardous and often unpredictable so its suggested to have proper inspection of your materials to ensure quality and endurance.

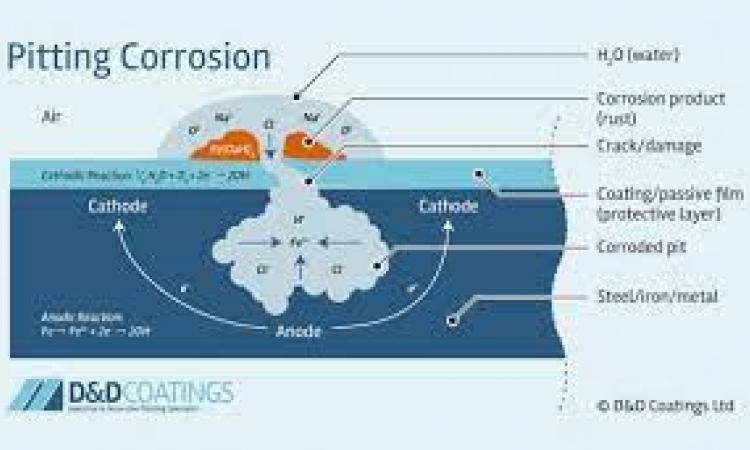

We performs and evaluate carbon steel, low alloy steel and corrosion resistant alloys for sour service applications as per,NACE TM 0177 standard methods: Tensile Test, Bent-Beam Test & Ring Test. We execute Hydrogen Induced Cracking (HIC) testing to evaluate the susceptibility of low alloy steel and carbon steel to hydrogen embrittlement. Hydrogen Induced Cracking (HIC) testing is recommended to evaluate the resistance of pipeline and other materials to hydrogen induced cracking corrosion caused by hydrogen absorption from aqueous sulphide corrosion. The test is duly performed in accordance with NACE TM0284-2011. After the test the specimens are evaluated, examined microscopically and cracks if present, are reported and their ratios CSR (Crack Sensitivity Ratio), CLR (Crack Length Ratio), CTR (Crack Thickness Ratio) are calculated.