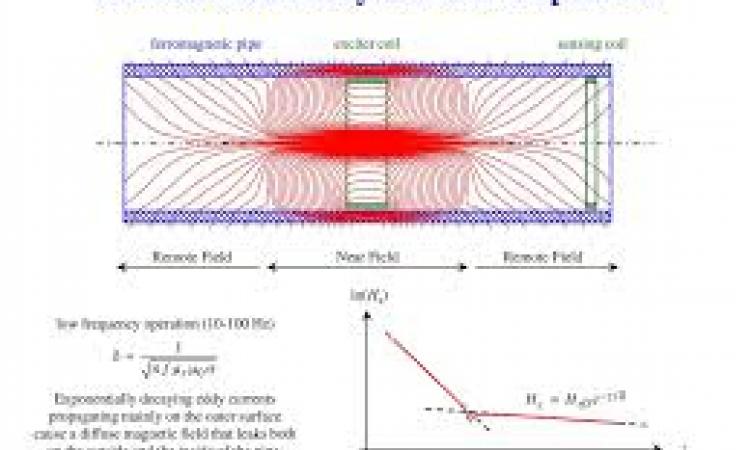

Near Field Testing

NFT technology uses two coils — a transmitter and a receiver. Typically, the receiver coil is close to the transmitter coil, taking advantage of the transmitter’s near-field zone — that is, the zone where the magnetic field from the transmitter coil induces strong eddy currents, axially and radially, in the tube wall. NFT probes operate within the same frequency range as RFET probes..

NFT is specifically suited to detecting corrosion, erosion, and pitting inside carbon steel tubing. NFT is perfect for fin-fan tube heat exchangers because eddy currents do not go through the wall of the tube. NFT is also much more sensitive to defects close to structures such as support plates and tube sheets.

Advantages of Field Inspection Technique

Around 500 tubes can be inspected in 10 hrs.

No need for an external reference coil

Operator dependability is low

Unaffected by structures such as support plates and Tube sheets.

Limitations of Magnetic flux leakage Inspection

No detectability on OD side of the tube.

Limited sensitivity to cracks .