Risk Based Inspection

Dashinspectorate offer Qualitative, Quantitative, and Semi-Quantitative Risk Based Inspection Methodologies in Oil/Gas, Power, Petrochemicals and Marine sector

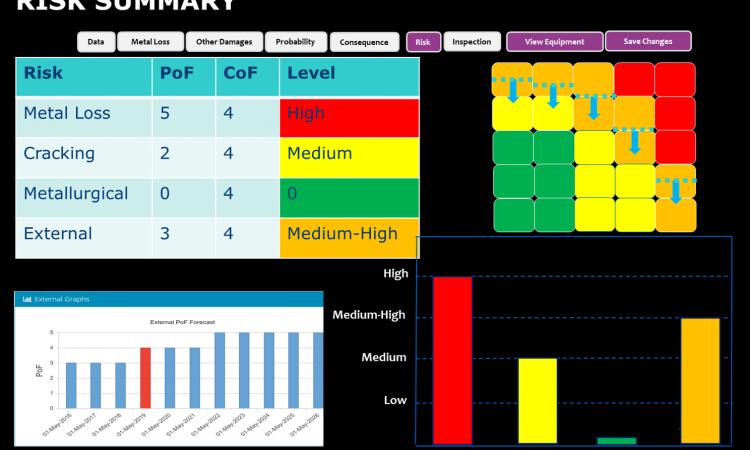

Dashinspectorate has enhanced the process and methodology of Risk based inspection (RBI) and Reliability Centred maintenance (RCM) analysis, by using the self-developed RBI software Dashinspectorate AIMS (Asset Integrity Management Software). It is a comprehensive software application developed specifically to assist facilities implement effective risk based inspection/ analysis, mechanical integrity and process safety programs.

Dashinspectorate possess decades of immense experience in Oil/Gas, Power, Petrochemicals and Marine sector. We provide RBI assessment/ programming for various process units, especially for,

Different process units of Oil Refineries and Gas plants.

Oil production platform.

FPSO (Floating production storage and offloading).

FLNG (Floating liquefied natural gas).

Onshore petroleum storage farms.

Petrochemical/ Power plants.

We offer Qualitative, Quantitative, and Semi-Quantitative RBI Methodologies, which would be performed by professional team comprises RBI team leader, Inspection Engineers, RBI/ API Inspectors, Corrosion Engineers, Metallurgists, Chemical & Process Engineers, NDE Specialists etc. Since Dashinspectorate is having established asset integrity inspection task force along with all advanced inspection/ testing facilities, we are able to club the RBI assessment and required field inspection activities to produce an effective inspection package.

Why RBI?

Risk-Based Inspection (RBI) is an analysis methodology in which assets are identified for inspection based on their associated risks. RBI process, the potential risks are being analysed by qualitative or quantitative assessment of the probability of failure (PoF) and the consequence of failure (CoF) associated with each equipment item, piping circuits included, in a particular process unit. RBI identifies, assesses and maps industrial risks (due to potential damage mechanism), which can compromise equipment integrity in both pressurized equipment and structural elements. RBI addresses risks that can be controlled through proper inspections and analysis. During the RBI process, engineers design inspection strategies (what, when, how to inspect) that most efficiently match forecasted or observed degradation mechanisms.

RBI is a method to prioritize and manage the efforts of an inspection program and provides a methodology for determining the optimum combination of equipment inspection methods, scopes and frequencies.

Dashinspectorate AIMS (Asset Integrity Management Software)

Dashinspectorate AIMS provides tools for analysing and processing data that is managed in an Asset Integrity Management system. Data is analysed to determine the state of assets, its reliability, trends, potential risks, and probability of failures associated with that Asset. Based on the gathered data and associated analyses, the impact of projected changes are derived by Dashinspectorate AIMS. This facilitates educated recommendations and creation of Asset strategies for future asset maintenance.

Dashinspectorate AIMS is developed with a Risk Based Inspection approach following API 580 and API 581 principles for a comprehensive quantitative, semi-quantitative and qualitative analysis. The software is an online Web portal, with centralized data, that can be accessed from any location or computer, using web browsers. Quick and easy Updates. Store asset data and control documents in one place reducing redundancy and streamlining record keeping.

Benefits of RBI

Reduced likelihood of loss of containment; thus reducing downtime by avoiding unplanned outages

Providing strategies to achieve desired level of mechanical integrity (MI) and reliability.

Reduced inspection cost by specification of appropriate inspection techniques and extending inspection intervals where appropriate

Legislative compliance

Focusing resources on areas where maintenance is most critical and leads to More effective turnaround planning

Enabling better budgeting and planning for future inspection, maintenance, and run-repair-replace decisions

Why RBI?

Regulatory driven, Liability driven, Profit driven, Safety driven. "It is a tool to prioritize inspection budget, using the experience of the whole industry"

Integrity management services In support of client

Standards by:

American Petroleum Institute (API MPMS)

International Standards Organization (ISO)

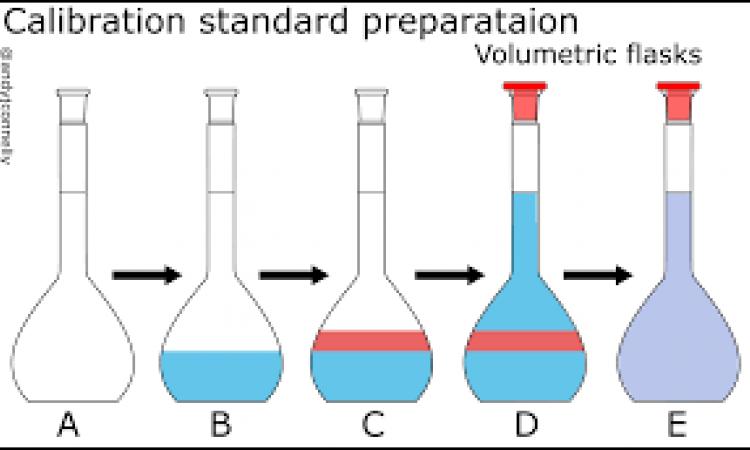

Steel Tank Institute (STI).Liquid Calibration Method.

RISK BASED INSPECTION

Risk Based Inspection (RBI) is a proven methodology used to optimize inspection activities to ensure pressure systems integrity management through a systematic risk analysis. RBI is based on a risk assessment where this risk identifies the safe operating windows for particular process equipment, for example static equipment or pipework, via consideration of the likelihood of failure and consequence of failure.

risk based inspection

Our RBI methodology adheres to international codes and standards, replacing time based inspection with a number of significant advantages:

Reduced operational risk

Increased plant availability and reduced unplanned outages

Consideration of types of degradation and damage mechanisms

Optmised inspection and maintenance costs without compromising safety or reliability

A flexible technique able to continuously improve and adapt to changing risk environment

Inspection techniques and methods clearly defined and based on thorough understanding of potential failure modes

Risk based inspection is however largely misunderstood. In today’s Oil and Gas industry it is often poorly implemented and this greatly reduces its effectiveness. Most integrity service providers sell the technique purely on the capabilities of their own proprietary risk based inspection software and pay little attention to the relevant damage mechanisms in play and the practical / theoretical methodologies of mechanical integrity.

Dashinspectorate’s materials, inspection and engineering expertise allows us to deliver an RBI that encompasses all the benefits that risk based inspection methodologies can offer.

WE IMPLEMENT RISK BASED INSPECTION FOR:

risk based inspection

Our independent approach means that, unlike our competitors, we are not restricted to a single risk based inspection software and are therefore able to implement the appropriate data to meet our client’s needs. We not only have working relationships with a number of leading RBI software providers but also have considerable experience working with older assets where an existing system simply needs to be updated or modified.

Need help or have a question?

- Risk Based Inspection

- Pipeline Inspection Management System

- Pipeline Inspection Management System (Onshore)

- Structural Integrity Management System (SIMS)

- Pressurized Equipment Management System

- Inspection Scheduling Management System (ISMS)

- Wellhead Integrity Management System (WHIMS)

- Computerized Maintenance Management System

- Asset Performance Management System

- Safety Integrity Level (SIL Study)

- Reliability Centered Maintenance (RCM)

- Reliability, Availability and Maintainability (RAM)

- Condition Based Monitoring (CBM)

- Condition Assessment Studies (CAS)

- Corrosion Management Plan (CMP)

- Corrosion Risk Assessment Study (CRAS)

- Asset Life Extension Studies

- Fitness For Service

- Close Interval Potential

- Direct Current Voltage Gradient

- ISO 55001 (Asset Management Systems)

- RBI Technical Training