Risk Based Inspection (RBI)

Risk Based Inspection - VAIL-Plant Software

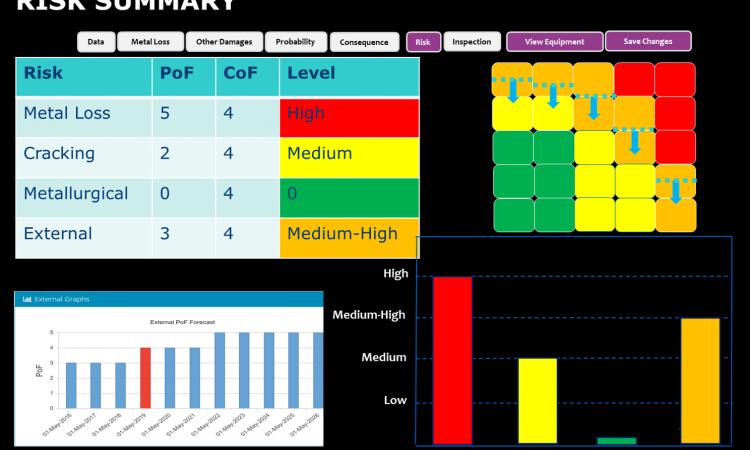

Risk-based Inspection is a type of maintenance business process used to analyze equipment, including pressure vessels, heat exchangers and piping in industrial plants. It is a decision-making technique to optimize inspection plans.

The theory of Risk-based Inspection is built upon the concept that the risk of failure can be assessed in connection with a level that is acceptable, and inspection and repair used to assure that the level of risk is below that acceptance limit.

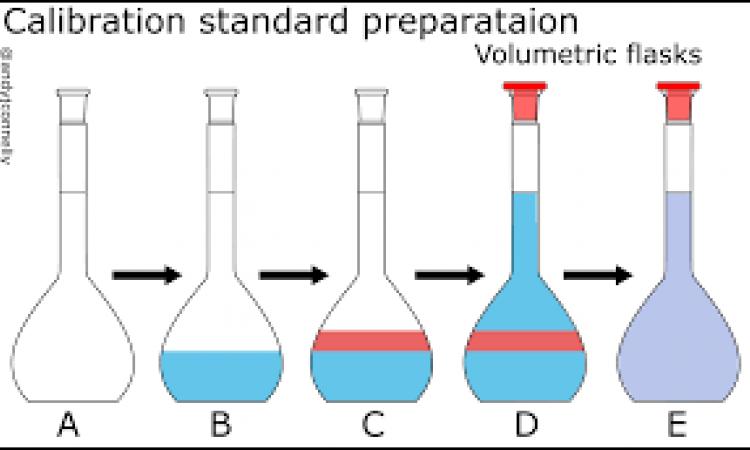

Led by industry experts, including senior consultants and engineers, DASH's unparalleled Risk-based Inspection programs feature a total quality assurance approach. We employ a comprehensive and structured approach - in line with industry guidelines like API 580, 581 and API 571 - to analyze the potential risks of each asset by evaluating their current operating conditions in terms of the probability and the consequence of failure, providing our clients with a unique view of the condition of each asset.

Benefits of RBI:

- De?nes and rates the risk levels of all components.

- Identifies the potential to reduce production losses during turnaround inspection.

- Increases con?dence in equipment integrity and reliability.

- Minimizes risk to health, safety and the environment.

- Maximizes resource utilization.

- Improves operating efficiency.

RBI Deliverables:

- Corrosion Loop Drawings

- Inventory Group Drawings

- Corrosion and Inspection Strategy Document

- Risk-based Inspection (RBI) Findings

- Inspection Isometric Drawings for Equipment and Piping

- Integrity Operating Window

- Asset Passports

Risk-based inspection incorporates the below-mentioned processes:

- Pipeline Integrity Management System (PIMS-Onshore and Offshore)

- Structural Integrity Management System (SIMS)

- Pressurized Equipment Management System (PEMS)

- Inspection Scheduling Management System (ISMS)

- Wellhead Integrity Management System (WHIMS)

- Asset Performance Management System (APMS)

- Computerized Maintenance Management System (CMMS)

Need help or have a question?

- Risk Based Inspection

- Pipeline Inspection Management System

- Pipeline Inspection Management System (Onshore)

- Structural Integrity Management System (SIMS)

- Pressurized Equipment Management System

- Inspection Scheduling Management System (ISMS)

- Wellhead Integrity Management System (WHIMS)

- Computerized Maintenance Management System

- Asset Performance Management System

- Safety Integrity Level (SIL Study)

- Reliability Centered Maintenance (RCM)

- Reliability, Availability and Maintainability (RAM)

- Condition Based Monitoring (CBM)

- Condition Assessment Studies (CAS)

- Corrosion Management Plan (CMP)

- Corrosion Risk Assessment Study (CRAS)

- Asset Life Extension Studies

- Fitness For Service

- Close Interval Potential

- Direct Current Voltage Gradient

- ISO 55001 (Asset Management Systems)

- RBI Technical Training