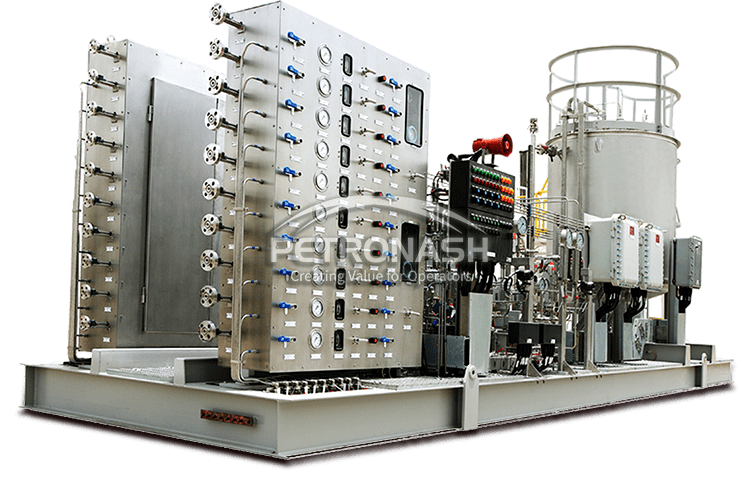

Chemical Injection Packages

The Chemical Injection Package serves the purpose of injecting a precise and accurate amount of chemicals into a system with the required back pressure, either continuously or intermittently.

Our Chemical Injection Package Includes

The purpose of injecting the chemicals into a system is to protect the mechanical integrity of the system from accelerated corrosion and prevent scale formation. The aim is also to control hydrate formation, prevent oxygen induced corrosion, emulsion breaker for rapid and sharp separation of water from oil, reduce wax formation, water treatment, Odorization, foam control etc.

Petronash specializes in designing and manufacturing all types of chemical injection packages in line with customer requirements and that meet various industry standards.

Key Features of Chemical Injection Packages

- Design in accordance to customer requirements, application, standard and design codes

- Pump selection as per process parameter.

- Material selection as per material compatibility with chemical.

- Use of proven system components.

- 3-D Modelling of all packages.

- Design Validation.

- System Performance Guarantee.

- After Sales System Support.

- As a worldwide leader in the oil and gas industry, Petronash applies innovation in the manufacturing of different types of chemical injection packages, as described above.